Materials Testing

Load Cell Central has assisted OEM’s with materials testing for over three decades. A large portion of our experience with materials testing is with quality control, with particular emphasis on dependability and repeatability. We also design systems for use with stress/destruction testing, check weighing, and pile testing.

These applications often require the recording the “peak”; the highest force measured during a test. We offer several different methods for measuring peak. Some of our standalone digital indicators are capable of holding maximum values. Our DSCUSB can log to a CSV file, which can be processed in Excel to show the max reading. With the proper configuration, our T24 telemetry system displays the peak value using the Log100 software.

Many our materials testing projects involve retrofitting a new system into an old design. This can pose difficulties when it comes to selecting appropriate load cells. Load Cell Central’s motivated staff, decades of experience, and manufacturing flexibility ensure that you can always turn to a custom load cell for even the most difficult applications. Customizable capacities, dimensions, materials, connectors, and outputs ensure you get a product that fits seamlessly into your existing system. Take a look at our other possible applications:

- Pile Testing

- Destructive Testing

- Check Weighing

- Packaging

- Quality Control

Case Study

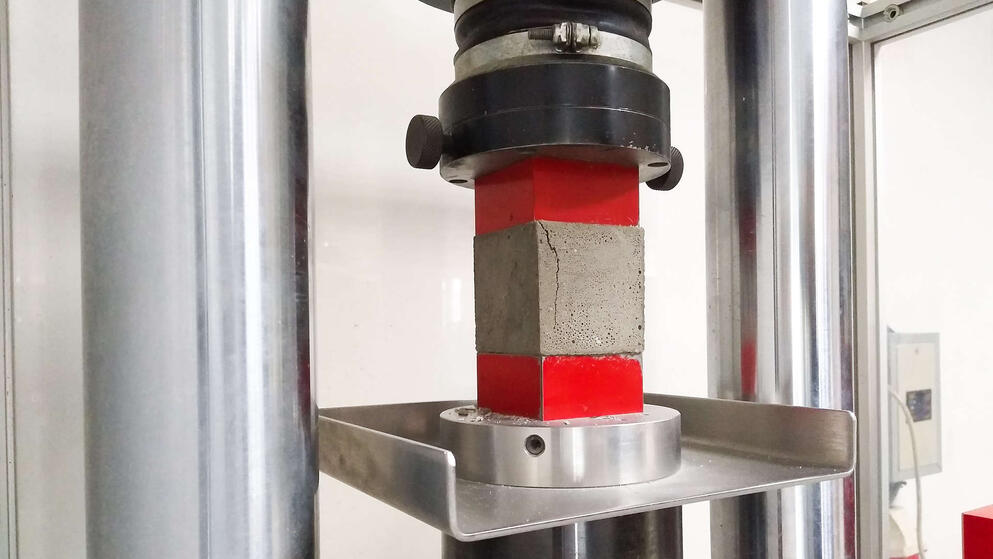

In 2012 we were asked to assist in measuring the force required to break a concrete pile. Concrete piles are low cost, pre-cast lengths of concrete in varying sizes used in building construction. Pile testing is essential to perfecting a concrete mixture. This test helps keep costs low, strength high, and allows a company to produce many separate mixtures for different applications. The special challenge in this application was the portability required by the customer, for tests at a client’s location.

We suggested a wireless solution for its ease of setup. Our T24 Telemetry system provides the data logging, peak measurements, and real time display of both weight and deflection. By logging to a CSV file, our customer can print and provide certificates “on the fly.”

For the load cells we provided four custom 100,000 lb canisters. We mounted wireless transmitters for each of the load cells and string potentiometers in an enclosure with a clear lid, allowing the operator to view the power LED indicators. We also provided a 24VDC power supply.

More recently, we participated in another pile testing application in which the test machines are permanent fixtures in the customer’s lab. These pile testing machines were custom built from the ground up and required a custom load cell to measure the forces generated, operating over a range of -65° Fahrenheit to 200° Fahrenheit, utilizing special strain gages and high temperature cable.

We engineered and built custom canister load cells in 30K, 60K, and 100K lb capacities. These load cells were designed specifically for these machines and are a perfect fit. This customer now has dozens of these load cells in different locations, and has recently requested drawings for 200K versions.