Tension Load Cells For All Applications

Tension load cells are categorized by the way the sensor deflects when experiencing strain. A tension load cell is pulled apart, rather than bent or compressed. Tension Links, S-Type load cells, Crane Scales, Canisters, and Pancakes are examples of tension-type load cells. No matter how specific or unique your application is, Load Cell Central can provide stock items off the shelf or design custom load cells to meet your needs.

Tension Load Cells and Compression/Tension Load Cells

Tension load cells are used commonly in overhead crane applications. We provide clamp sensors, like our DLWS, for the dead-end of crane wire ropes in order to measure the load without impacting the amount of headroom a crane operator has to work with. These systems are often used to a limiter switch for shutting down a crane that is experiencing an overload. This is done by using a small load cell controller that has programmable setpoints. These devices switch on and off a small voltage that is typically used as logic for a larger relay capable of powering down the entire crane.

We also offer tension link load cells, like our CTL2 or DCL10, for use above the hook of the crane. These applications are simpler and easier to install but do result in a loss of headroom between 12" to a few feet. Some of these applications use wireless technology to get the information to the crane operators, workers on the ground, or to one of our many wireless receivers capable of providing logging, analog output, serial output, printing, or relay outputs.

Load Shackles are another valid solution for some weight sensor applications where a dead end is not available and where headroom is of the utmost importance. These function similarly to a tension link load cell but save headroom at the cost of accuracy.

The simplest solution is to use a crane scale. Crane scales have started to include more features than in previous years, but they traditionally are a simple S-Type or Double Ended Shear Beam, inside a housing with a display attached. They allow calibration and zeroing like other indicators. Some include wireless technology and removable batteries.

Examples of Tension Load Cells

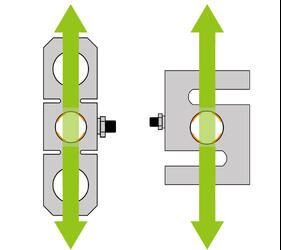

On the right is an example of a tension load cell being pulled apart, rather than bent or compressed. Imagine the force on a tow rope, and the rope is experiencing a tension force as pictured below. This is a good example of a tension load cell and measuring the weight of the load being lifted.

How Tension Load Cells Work:

How Tension Load Cells Work:

In a tension load cell, the strain gauges are set up parallel with the loading axis. When tension force is applied, the wire component of the strain gauge gets longer and thinner, thereby increasing its electrical resistance. This change in resistance is directly proportional to the amount of force applied, thereby making it possible to determine the amount of force applied.

For more information on how tension load cells work, please read our white paper titled Load Cell and Strain Gauge Basics

Tension Load Cell Applications

Tension load cells are used wherever tensile, pulling, towing, mooring or other tension force needs to be measured.

Some examples are:

- Crane and hoist weighing

- Overload protection for crane/hoist scales

- Tank and hopper scales

- Tensile strength measurement

- Towing loads and cable forces

- Mooring strength

- Hanging scales

- And many other types of tension load cell application

How do tension load cells work?

Both tension and compression load cells work by means of a strain gauge attached to the surface of the load cell through which a measured electrical current is run. When weight is applied to the load cell, the strain gauge is stretched or compressed causing a change in resistance of the current running through the strain gauge. In a tension load cell, the change in the shape of the load cell is caused by tension force.

For more information, please refer to our white paper: Strain Gauge and Load Cell Basics

A tension load cell is a type of force sensor transducer that is used to measure the tension or pulling force applied to it from a mechanical load and converts it into an electrical signal to be measured digitally by equipment.