How a Load Cell Works

force, whether it be tension, compression, or pressure, into an electrical signal. The

magnitude of the electrical signal is directly correlated to the magnitude of the force exerted on the load cell.

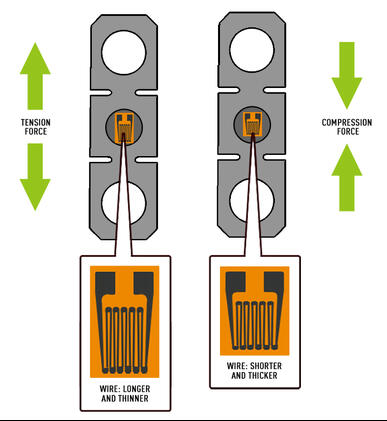

Strain gauge load cells are widely used in industrial applications as the most prevalent type of load cell. These load cells consist of a rigid metal body, also referred to as a "spring element" with strain gauges securely affixed to it. When a force is exerted on the load cell, the spring element undergoes slight deformation, which it promptly rebounds from due to its elastic properties.

As the shape of the spring element alters, the shape of the strain gauges affixed to it changes as well. Consequently, the electrical resistance of the strain gauges either increases or decreases. By passing an electric current through the strain gauges, the variation in resistance is reflected in the measured voltage output. Since this change in output is directly proportional to the applied weight, the weight of the object can be determined based on the observed voltage change.

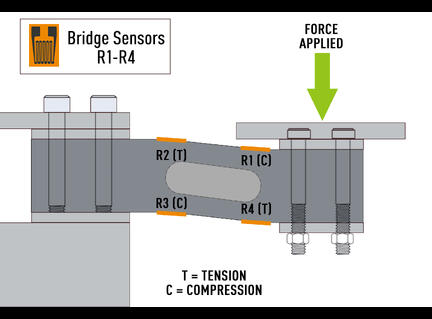

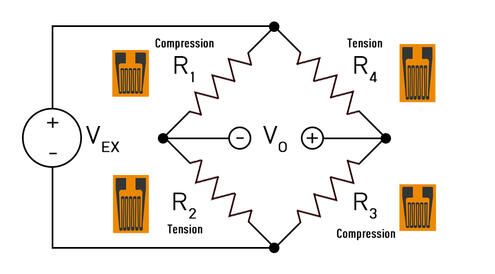

To ensure that the spring element deflects with minimal permanent deformation, the

deflection must be kept to a minimum. Calculations relying solely on the minute

resistance change of a single strain gauge may lack precision and be susceptible to

errors. To compensate for this, and to achieve a high degree of accuracy in load cell

measurements, multiple strain gauges are employed. These strain gauges are arranged

in a Wheatstone bridge configuration, where the overall change in resistance across all

four strain gauges can be determined using Ohm's law and an appropriate equation.

| VO = | R3 | – | R2 | × VEX | ||

| (R3 + R4) | (R1 + R2) |

Blogs and Video for More In-Depth Information on Load Cells:

Load Cell and Strain Gauge Basics Load Cell Terminology Load Cell Types and Uses

Understanding Load Cell Specifications System Basics Load Cell Accuracy

Testing and Troubleshooting a Load Cell

Types of load cells

Beam Load Cells

Beam load cells are commonly utilized in applications such as vessel/tank weighing and

floor scales. These load cells come in three main types: bending beam, single-ended

shear beam, and double-ended shear beam. The bending beam load cell is a cost-

effective option and is typically suitable for lower-capacity applications. It is designed

with a beam that bends when a force is applied, allowing for the measurement of weight or force. In the single-ended shear beam load cell, the load cell is mounted on one

end, while the force is applied to the opposite end. This configuration allows for

accurate measurements in various weighing applications. The double-ended shear

beam load cell is mounted on both ends, and the force is applied to the middle of the

load cell. This type of load cell is particularly well-suited for medium to high-capacity

weighing requirements. It provides robust and reliable measurements, especially for

higher weight capacities.

Single Point (binocular)

Single Point (binocular) load cells are compression load cells with a lower capacity

range. They are specifically designed for applications such as deli scales, bench

scales, and checkweighing. These load cells are known for their moment compensation capability. The structure of the load cell body is modified, and the strain gauges are arranged in a manner that enables accurate weight measurement regardless of the load placement on the scale platform. This flexibility in load placement ensures that the load cell consistently provides precise and reliable readings. Single Point load cells are ideal for applications where weight distribution may vary or where there is a need for versatile load placement. They offer excellent performance and accuracy in deli scales, bench scales, and checkweighing applications.

Pancake (shear web type)

Pancake load cells, also known as shear web-type load cells, are commonly employed

in manufacturing environments, particularly in car manufacturing. They play a crucial role in

measuring durability and determining product failure limits during destructive testing

processes. Additionally, they are well-suited for verifying force measurement in press

applications. Pancake load cells are designed to be versatile in their usage. They can be sandwiched between two components to measure compression forces accurately. Alternatively, they can be used in tension applications by utilizing the threaded holes provided. Pancake load cells offer precise and reliable force measurement capabilities, making them indispensable tools in various industrial applications. Their ability to withstand high forces and provide accurate readings makes them well-suited for demanding environments such as car manufacturing and destructive testing scenarios.

Canister (column)

Canister (column)

Canister load cells, also known as column load cells, have been a longstanding design in the field of load cells. This particular configuration is highly suitable for higher capacity requirements. Canister load cells excel in heavy-duty applications, notably in truck scales and railroad scales. Calister load cells are available in two variations: compression-only or tension/compression. The compression-only design is primarily intended for measuring forces in compression, while the tension/compression variant can accurately measure both tension and compression forces. This flexibility makes them well-suited for a wide range of applications. Similar to shear web load cells, certain canister load cell models are equipped with threads that enable pulling applications, providing even greater versatility in force measurement. Canister load cells have a long history of reliability and robustness, making them a preferred choice in demanding scenarios that require accurate and precise measurements. Their exceptional performance in heavy-duty applications such as truck scales and railroad scales demonstrates their capability to handle substantial forces with precision.

S-Type

S-type load cells are commonly utilized in hanging scales or applications involving the weighing of suspended vessels. These load cells are designed to be versatile, capable of measuring both tension and compression forces. In tension applications, S-type load cells can be conveniently suspended from shackles and pulled to accurately measure the applied force. On the other hand, in compression applications, they can be mounted between two items using the provided top and bottom threads, allowing for precise measurement of compressive forces. The flexibility of S-type load cells makes them well-suited for a range of applications where both tension and compression forces need to be measured. typically

Tension Link

Tension Link

Tension Link load cells are highly versatile force transducers designed specifically for measuring tension forces along a straight line. These load cells offer exceptional flexibility and come in a wide range of capacities to suit various applications. Moreover, they can be customized to meet the demands of extremely heavy-duty scenarios. These load cells find extensive use in various applications such as mooring and submersible testing, crane scales, and towing/pull force measurement. They excel in scenarios where precise measurement of tension forces is crucial. The versatility of Tension Link load cells allows them to be deployed in diverse settings, providing accurate and reliable tension force measurements.

Load Pin

Load pin load cells are specifically designed to replace traditional pins or axles in applications where force needs to be measured. These load pin load cells offer a highly customizable design and structure, making them suitable for use in a wide range of scenarios, including those involving very high capacities. The load pin load cells serve as a direct replacement for existing pins or axles, seamlessly integrating into the system. Their customizable nature allows for precise adaptation to meet the unique requirements of each application, especially where applications require heavy loads that need to be accurately measured. The versatility and customizability of load pin load cells make them a valuable choice for

a variety of industries and applications.

Thru-Hole Load Cells

Thru-Hole Load Cells are specifically designed for applications such as anchor and fastener testing, as well as boat mooring tests. Thru-hole load cells offer exceptional versatility and can be utilized for both tension and compression measurements. Thru-Hole Load Cells are highly adaptable and can be installed between two parts to accurately measure compression forces. Alternatively, they can be pulled from opposite directions, similar to a link in a chain, to measure tension forces. The versatility of Thru-Hole Load Cells makes them indispensable in various industries. Whether it's testing anchor and

fasteners, conducting boat mooring tests, or other similar applications, these load cells

provide precise and reliable force measurement capabilities.

Select a Load Cell by Capacity

Low Capacity Load Cells

Capacities from 25 grams to 150 Pounds

Mid-Range Load Cells

Capacities from 200 to 20,000 Pounds

High Capacity Load Cells

Capacities from 25,000 to 1 million Pounds